Experts in today’s electronic engineering. Innovators of tomorrow’s technologies.

Your most valuable asset for Electronic Design & Engineering.

We achieve that through:

Elite Experience

In the world of electronic circuit board design and engineering solutions, no one does it better than us. Our proven methodologies and vast experience focus on quality and results. We understand today’s technology and tools, and our professional team of engineers and designers have what it takes to execute. Want proof? Just ask some of the world’s most sophisticated companies we work with, including Amazon, Lockheed, Northrop Grumman, Siemens, and Zoox.

True Partnership

We don’t take the word partnership lightly. Our culture and process dictate a constant cycle of communication throughout the design process. We listen, share our experience and work collaboratively with you through the sometimes changing requirements of a project. As a service-oriented company, we never miss an opportunity to do what it takes to meet your needs. Our open-door policy is one of proactive communication.

We know choosing a new engineering partner can feel like a risky undertaking. We assure you we understand what it takes to succeed. Our customers range from start-ups to multi-billion dollar giants. What they have in common is a need for high-level process sophistication that meets their design and data protection requirements, a desire for high-quality work delivered on time, and, most importantly, a high level of attention and flexibility. Our bottom line: when you succeed, we succeed.

Care & Commitment

Our dedication to our clients is simple; we care a lot. From deadlines and budgets to IP protection, attention to detail, and delivery, we are laser-focused on customer satisfaction. We are not in it for the one-off project or single PCB design; we are always striving to have a customer for life. We take pride in our workmanship. We are always 100% in.

A few of our amazing customers

Thanks so much for the support and working so many long days and weekends to help push this out. We at NGC have been very impressed with the team’s execution and dedication on this challenging project.

– Northrop Grumman

– Garrett Motions

The “monster” board is doing well! The board was able to run software on Day 1 when we got it into the lab, and it’s been a great bring up experience. Our great teamwork has turned out really well.

😊

– Synopsys

– Amazon

– Siemens

MARKETS WE SERVE

GET IN TOUCH WITH US TO BOOK

A PRESENTATION

The Tools We Use Everyday

Certifications & Compliance

The International Traffic in

Arms Regulations

National Institute of

Standards and Technology

THOUGHT LEADERSHIP

5 Things You Should Know About NRE

- March 4, 2021

Offshoring to China More Expensive Than United States

- March 4, 2021

Avoiding Risk with a Thorough BOM Scrub

- March 4, 2021

Cut Tape vs. Tape and Reel

- March 3, 2021

Why You Should Always Use a Solder Sample

- March 3, 2021

Fixturing vs. Paneling in SMT

- March 3, 2021

Reducing the Cost of RoHS Compliance

- March 3, 2021

When Do You Repair and When Do You Scrap PCBs?

- March 2, 2021

Moisture Sensitivity Levels Explained

- March 2, 2021

Don't Underestimate Solder Paste Inspection

- March 2, 2021

Counterfeit Component Risk Management

- March 2, 2021

Best Mid-Sized San Jose PCB Assembly Companies

- March 2, 2021

1 Minute Guide To Supplier Management

- March 1, 2021

How To Improve Quote Turnaround Time

- March 1, 2021

5 BOM Obsolescence Management Tips

- March 1, 2021

The 3 Keys to Customer Satisfaction

- March 1, 2021

3 Most Common PCB Assembly Defects

- March 1, 2021

Managing SMT Attrition

- February 25, 2021

What is a Lean Office?

- February 25, 2021

Do Apple and Cisco Need Should Cost Analysis?

- February 25, 2021

Why Haven’t I Heard of Should Cost Analysis?

- February 25, 2021

Why Price Isn't Always Everything

- February 25, 2021

Several Technologies Converging to Drive PCBA Industry Demand

- February 24, 2021

5 Benefits of Surface Mount Fixtures

- February 24, 2021

Top 5 Lean Office Pitfalls

- February 24, 2021

5 Tips for BOM Structure

- February 24, 2021

ISO Certification - The 4 Basic Certifications Explained

- February 24, 2021

3 Major Ways Mentor Valor MSS Assists in PCBA Assembly

- February 23, 2021

Surviving Downturns With Your Contract Manufacturer

- February 23, 2021

3 Excess Inventory Solutions

- February 23, 2021

Security of Supply: High Probability Electronic Component Sourcing

- February 22, 2021

What is Selective Soldering?

- February 22, 2021

How To Use SiliconExpert to Reduce Supply Chain Risk

- February 22, 2021

Through-Hole vs. Surface Mount

- February 22, 2021

PCB Ionic Contamination Test

- February 22, 2021

Contract Manufacturing Cost Control: 4 Key Software Tools

- February 22, 2021

1 Million Reasons You Need SiliconExpert

- February 22, 2021

4 Ways to Eliminate Late Deliveries

- February 19, 2021

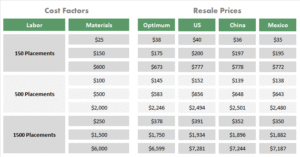

Contract Manufacturing Price Cheaper in Mexico Than China

- February 19, 2021

What China’s Third Plenum Means for Offshore Manufacturing

- February 19, 2021

4 Ways Contract Manufacturing Partners Should Do Cost Reduction

- February 19, 2021

3 Myths Drive EMS Vendor Selection Mistakes

- February 19, 2021

PCOLA/SOQ Explained

- February 18, 2021

What is a Complementary Test for PCBA Assembly?

- February 18, 2021

Complexity Index for PCBA Assembly

- February 18, 2021

What's 'World Class' for Solder Joint DPMO?

- February 18, 2021

Jabil Review

- February 17, 2021

TTM Technologies Review

- February 17, 2021

Viasystems Review

- February 17, 2021

Avnet vs. Arrow Electronics

- February 17, 2021

Future Electronics Review

- February 17, 2021

Benchmark Electronics Review

- February 16, 2021

Plexus Corp Review

- February 16, 2021

Flextronics Review

- February 16, 2021

Review: Sanmina vs. Celestica

- February 16, 2021

Xilinx v. Flextronics: Insight to a Gray Market

- February 16, 2021

Quick and Easy Should Cost Analysis

- February 15, 2021

4 Documents Required to Quote a PCB Assembly

- February 15, 2021

Should I Tell My Contract Manufacturers What Others Have Quoted?

- February 15, 2021

Contract Manufacturing Price Model: Cost Plus

- February 15, 2021

5 Rules to Finding the Right-Size Contract Manufacturer

- February 15, 2021

Why Does Price Vary Between Contract Manufacturers?

- February 12, 2021

How Are Electronic Components Priced?

- February 12, 2021

Why Should Cost Analysis?

- February 12, 2021

Should Cost Examples For PCB Assembly

- February 12, 2021

How To Get Suppliers Costed BOMs

- February 12, 2021

Should Cost Analysis vs. Strategic Sourcing

- February 12, 2021

How Much Should NPI PCBAs Cost?

- February 11, 2021

DPMO And How It Correlates In The Six Sigma Method

- February 10, 2021

What is Product Realization?

- February 10, 2021

How Long Does a PCBA Quote Take?

- February 10, 2021

What's the Difference Between Margin and Mark-Up?

- February 10, 2021

What is Should Cost Analysis?

- February 10, 2021

Conflict Minerals Quick Facts

- February 2, 2021

On Time Delivery Definition and Measurement

- January 21, 2021

Embedded Microstrip Transmission Lines in RF PCB Design

- April 23, 2019

Microstrip Transmission Lines in RF PCB Design

- April 5, 2019

RF PCB Stackups: X and Y Axis Isolation

- March 23, 2018

RF PCB Transmission Line Width

- January 25, 2018

Transmission Lines in RF PCB Design

- January 18, 2018

Toward A More Rational Silkscreen

- January 28, 2016

PCB Surface Finishes Comparison: HASL, OSP, & ENIG

- July 26, 2015

How are Electronics Components Priced? [Podcast]

- June 26, 2015

4 KPIs Crucial to On-Time Delivery [Podcast]

- June 4, 2015

Contract Manufacturing Price Model: Cost Plus [Podcast]

- May 18, 2015

How to Place Breakaway Rails in a PCB Design

- April 22, 2015

On Time Delivery [Podcast]

- April 8, 2015

Solder Paste: What Should I Be Using for My Product?

- April 7, 2015

Are Local Fiducials Necessary?

- April 1, 2015

Schematic Symbol Properties for DxDesigner

- February 18, 2015

DxDesigner Tutorial: Schematic Symbol Pins

- February 13, 2015

DxDesigner Tutorial: Pin Name Abbreviations

- February 12, 2015

DxDesigner Tutorial: Schematic Symbol Naming Conventions

- February 12, 2015

Mentor Expedition Library Tutorial: Renumber Pins Referenced by Parts

- February 11, 2015

About Optimum's Library Management Service

- January 29, 2015

Mentor Expedition Library Tutorial: Add Dimension Data to a Cell

- January 27, 2015

Mentor Expedition Library Tutorial: Make Schematic Symbols from CSV Files

- January 26, 2015

Mentor Expedition Library Tutorial: Delete a Cell Referenced by a Part

- January 23, 2015

Mentor Expedition Library Tutorial: Display Control Settings for PCB Library

- January 21, 2015

Mentor Expedition Library Tutorial: Making PCB Library Components from Existing Parts

- January 20, 2015

Common PCB Library Errors

- January 5, 2015

PCB Library Management Part Five: Miscellaneous Modifiers

- December 19, 2014

Pin Vs. Gate Swapping in PCB Design

- November 14, 2014

Switching Power Supply PCB Layout Seminar

- September 25, 2014

How to Use a Silkscreen to Identify PCB Components

- September 22, 2014

What Is A PCB?

- September 2, 2014

PCB Layout Prices Are Hard To Compare

- July 22, 2014

How Are PCB Layout Jobs Priced?

- July 22, 2014

PCB Design Tips: 5 Need-to-Know Component Assembly Methods

- July 10, 2014

Schematic vs. Netlist: A Guide to PCB Design Integration

- July 10, 2014

How to Place a PCB Bypass Capacitor: 6 Tips

- July 10, 2014

How to Bypass BGA Packages

- July 10, 2014

Outsourcing PCB Design: A Primer

- July 10, 2014

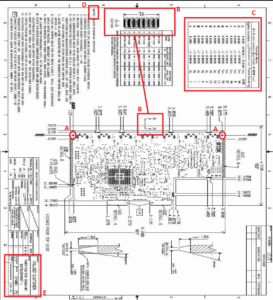

How to Read a PCB Fabrication Drawing

- June 26, 2014

5 Drafting Standards for PCB Drawings

- June 20, 2014

What is ODB++?

- May 7, 2014

Lean NPI at ODA Part One: Where Are We Now?

- March 31, 2014

HDI Layer Stackups for Large Dense PCBs

- March 31, 2014

DDR Memory Layout Design: Rules, Factors, Considerations

- March 31, 2014

Switching Power Supply PCB Layout Considerations – Towards a Better Switcher

- March 31, 2014

Clearance and Creepage Rules for PCB Assembly

- March 31, 2014

5 Clues You've Found the Right-Size Contract Manufacturer

- March 28, 2014

4 KPIs Crucial to On-Time Delivery

- March 4, 2014

Case Study: Converting Debug Tools into Manufacturing Fixtures

- February 21, 2014

Case Study: Bonding Failure on a Composite Structure

- February 21, 2014

Elite Experience

Care & Commitment

Our dedication to our clients is simple; we care a lot. From deadlines and budgets to IP protection, attention to detail, and delivery, we are laser-focused on customer satisfaction. We are not in it for the one-off project or single PCB design; we are always striving to have a customer for life. We take pride in our workmanship. We are always 100% in.

True Partnership

We don’t take the word partnership lightly. Our culture and process dictate a constant cycle of communication throughout the design process. We listen, share our experience and work collaboratively with you through the sometimes changing requirements of a project. As a service-oriented company, we never miss an opportunity to do what it takes to meet your needs. Our open-door policy is one of proactive communication.

We know choosing a new engineering partner can feel like a risky undertaking. We assure you we understand what it takes to succeed. Our customers range from start-ups to multi-billion dollar giants. What they have in common is a need for high-level process sophistication that meets their design and data protection requirements, a desire for high-quality work delivered on time, and, most importantly, a high level of attention and flexibility. Our bottom line: when you succeed, we succeed.

The Tools We Use Everyday

![How are Electronics Components Priced? [Podcast]](https://www.optimumdesign.com/wp-content/uploads/Podcast_cover-300x300.jpg)